| Home | About Us | Product | Know How | Contact Us | |||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||

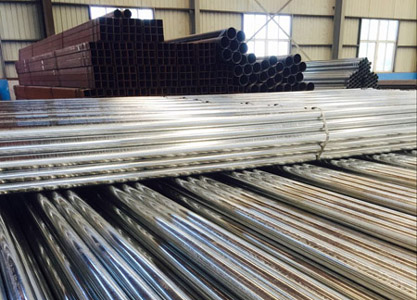

EN 10210 Hot finished structural hollow sections of non-alloy and fine grain steels Part 1: Technical delivery conditions Part 2: Tolerances, dimensions and sectional properties |

|||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||

| Standard: EN 10210-1, EN 10210-2 | |||||||||||||||||||||||||||||||||||||||||||||

| Material: S235JRH, 1.0039 | |||||||||||||||||||||||||||||||||||||||||||||

| Dimensions & Tolerance | |||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||

| EN 10210-1 and EN 10210-2 specify technical delivery conditions, tolerances, dimensions and sectional properties for hot finished hollow sections of circular, square, rectangular or elliptical forms and applies to hollow sections formed hot, with or without subsequent heat treatment, or formed cold with subsequent heat treatment to obtain equivalent metallurgical conditions to those obtained in the hot formed product. | |||||||||||||||||||||||||||||||||||||||||||||

| Manufacture: pipes to EN 10210-1 and EN 10210-2 shall be manufactured by hot finished or cold finished. Delivery Condition: the pipes shall be delivered in the conditions of two conditions, A qualities JR, J0, J2 and K2 - hot finished, B qualities N and NL - normalized, including normalized rolled. Inspection & Test: chemistry composition analysis, tensile test, impact test for qualities J2 and K2, welded pipes NDT of the weld, surface inspection and dimension check. |

|||||||||||||||||||||||||||||||||||||||||||||

| Keyword: EN 10210-1, EN 10210-2, SHS, RHS, CHS, Square Hollow Section, Rectangular Hollow Section, Circular Hollow Section | |||||||||||||||||||||||||||||||||||||||||||||

| Home | About Us | Product | Know How | Contact Us | |||||||||||||||||||||||||||||||||||||||||||||